Trust PDC to provide the ophthalmic device components you need.

Whether you manufacture non-invasive devices and instruments for diagnosis, implantable devices, or surgical systems related to the opthalmic field, precision components manufactured to exacting standards using the highest quality plastics is crucial. Because of this, ophthalmic device manufacturers need a company they can trust to provide precision micro molded parts that are of consistent high quality. At PDC, we pride ourselves on providing device manufacturers with the components they need on a scalable level.

For more than 30 years, opthalmic device manufacturers have trusted PDC for the micro molding expertise they need to create products that are crucial to patient care. We have provided parts for a broad range of ophthalmic devices and products.

- Access, Delivery & Closure Systems

- Pacemakers

- Neurostimulator Leads

- Tissue Biopsy

- Imaging Systems

When it comes to ophthalmic components, material choice is critical.

Many of the compounds used in micro molding are what are known as thermoplastic resins. These compounds are both exotic and highly engineered, and working with them requires an advanced level of expertise. At PDC, we're pleased to offer our clients just that. Our team of engineers are highly knowledgeable when it comes to thermoplastic applications, and our state-of-the art facility is modern, integrated, and dedicated to the medical and biotech industries.

PDC offers ophthalmic device components made from high-performance materials. Whether our clients need components made to offer strength and rigidity, or ones that are ultra-thin and flexible, we have the necessary knowledge and capabilities.

Micro molding is a specialized type of plastic injection molding that is used to manufacture extremely small plastic parts, typically with dimensions on the order of a few millimeters or less. Some examples of ophthalmology devices that are manufactured using micro molding capabilities include:

- Intraocular lenses (IOLs): Intraocular lenses are small, implantable lenses that are used to replace the natural lens of the eye during cataract surgery. Micro molding is used to manufacture the small plastic parts that makeup IOLs, including the haptic loops and the optic.

- Suture anchors: Suture anchors are small devices that are used to hold sutures in place during ocular surgery. Micro molding is used to manufacture the small plastic parts that make up these anchors, including the body and the suture loops.

- Vitreoretinal instruments: : Vitreoretinal instruments are specialized tools used in the diagnosis and treatment of retinal conditions. Micro molding is used to manufacture the small plastic parts that make up these instruments, including the handles, shafts, and tips.

- Microincisional instruments: Microincisional instruments are small, specialized tools used in microincisional cataract surgery (MICS), a type of cataract surgery that involves making very small incisions in the eye. Micro molding is used to manufacture the small plastic parts that make up these instruments, including the handles, shafts, and tips.

PDC’s vertically integrated facility enables technologies for the manufacturing of a wide range of ophthalmology devices, enabling the development of small, precise, and reliable tools for use in complex surgical procedures.

The Medical Device & Life Science markets require quality-manufactured micro molded components.

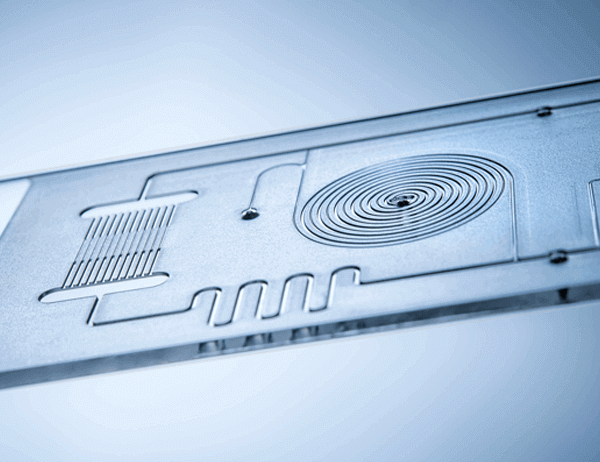

In the biopharmaceutical and genetic engineering industries, microfluidics are a crucial component.

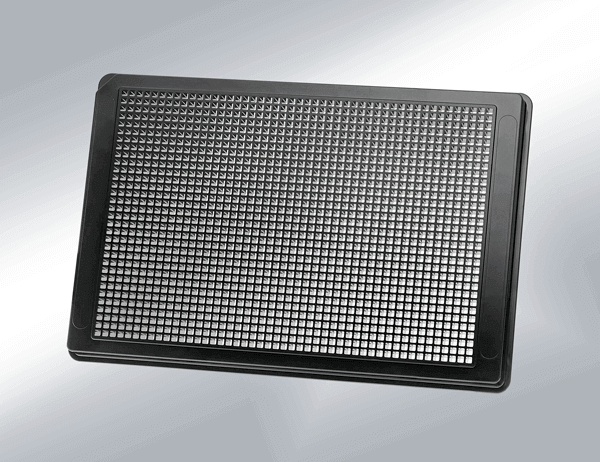

The healthcare and life science fields often rely on custom solid-and-film-bottom micro titer plates.

As pioneers in breakthrough technologies, PDC proudly manufactures products for the healthcare and life sciences industries that consistently meet exceedingly high requirements.