Watch our Facility Video

Get in Touch

PDC is a market leader in precision injection molding and value-added assembly, partnering with OEMs and Contract Manufacturers worldwide to deliver innovative micro-molded solutions to various medical device, diagnostics, and biotechnology markets. Share your specifications using the form below, and our team will be in touch to discuss your project.

We Offer Solutions For Your Industry

Within the medical sector, our capabilities support a range of segments within the industry.

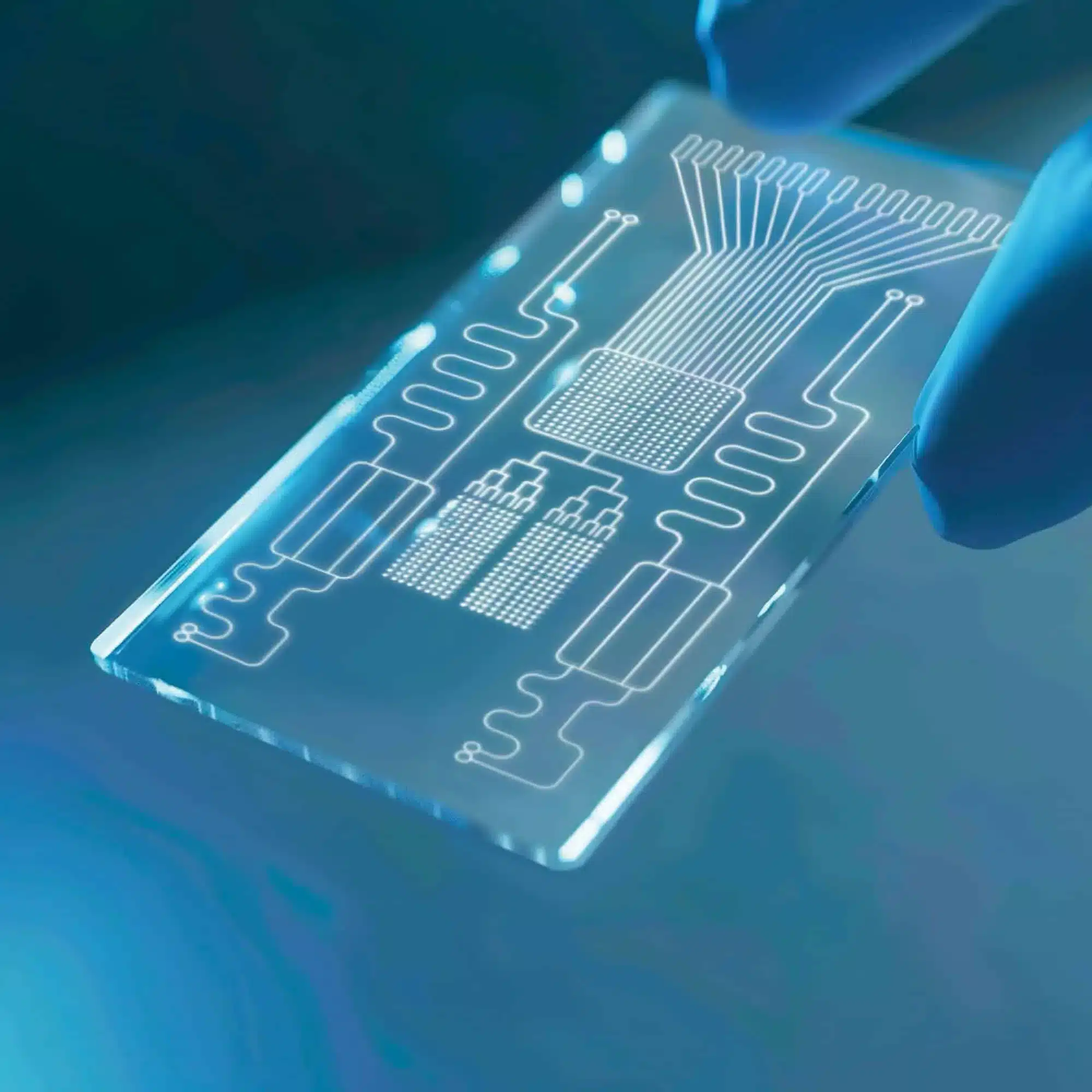

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. Explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. Explore the applications/products for advanced biopsy and key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. In this post, we’ll explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. In this post, we’ll explore three to five applications/products for advanced biopsy and delve into the key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

We're Here for You, From Start to Finish

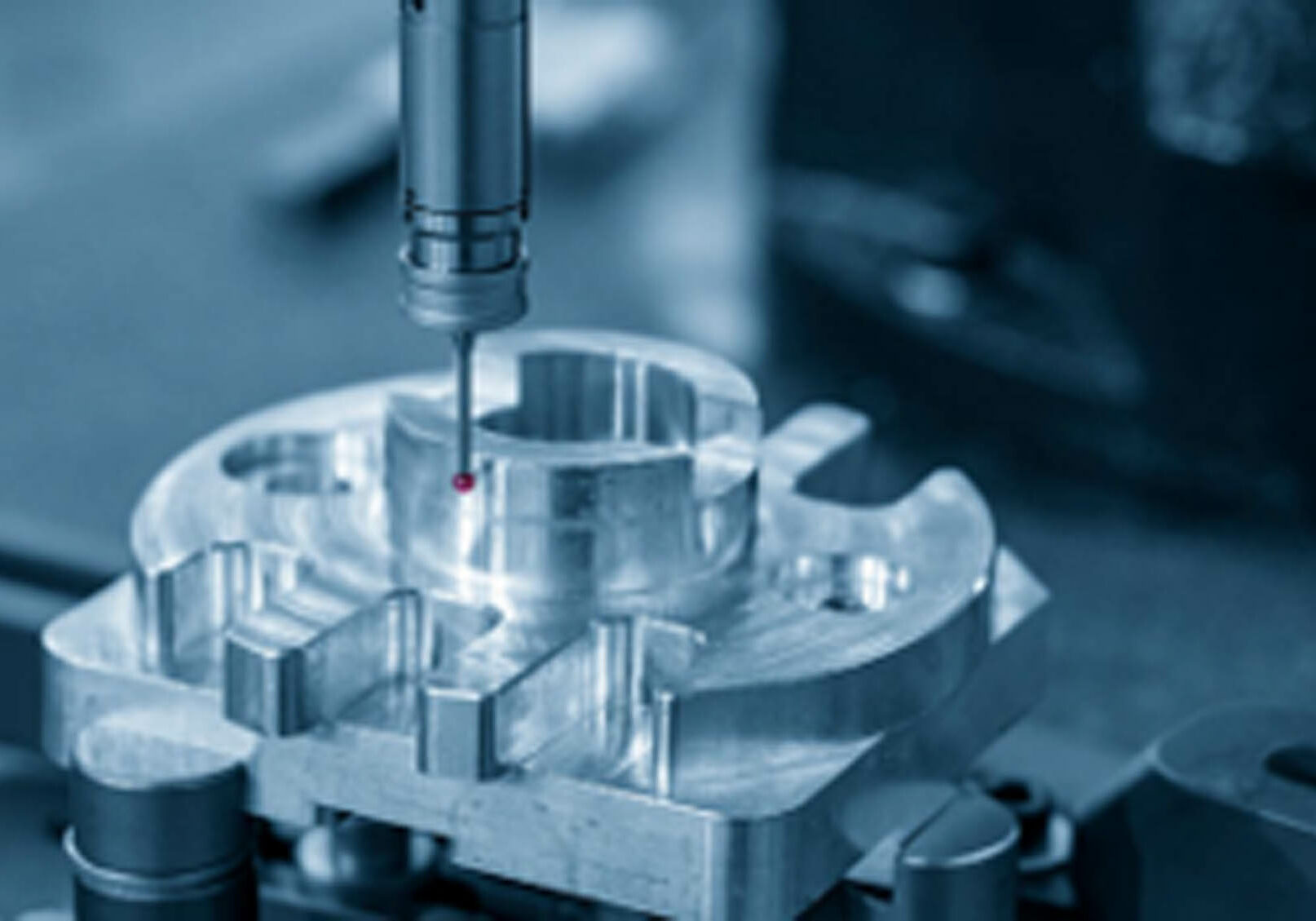

Our success is rooted in expertise in micro tooling, precision micro molding, and over-molding sub-assemblies. We excel in working with high-heat engineered resins, offering customization with various additives and colors. Our integrated model, covering ideation to in-house tooling and molding, reduces risk and accelerates speed to market. We can service 10 parts to 10 million parts.

1 Initial Contact

When you contact us with your project needs, our experts will touch base with you quickly.

2 Discovery

We'll then take the opportunity to learn more about your product requirements.

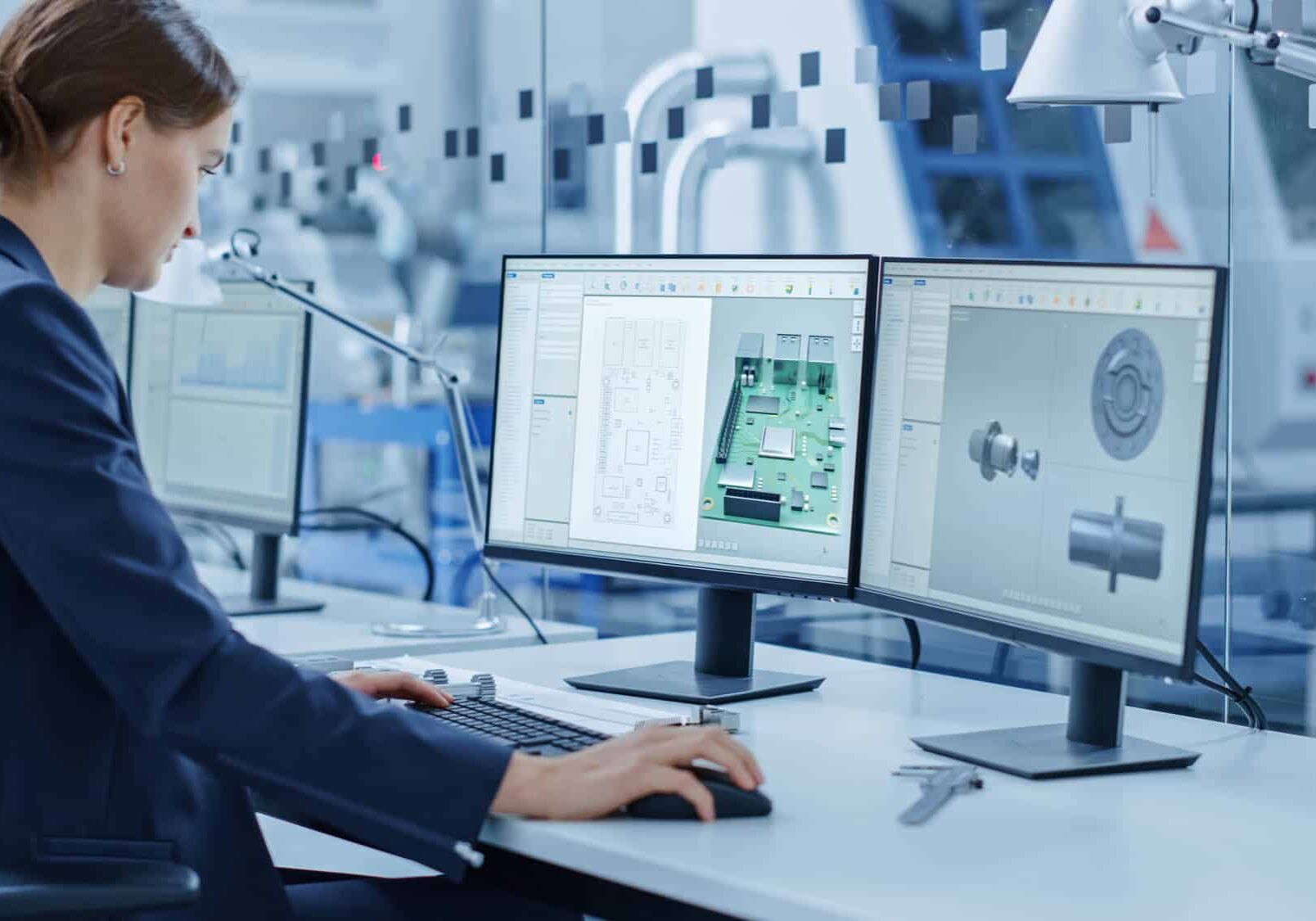

3 Design for Manufacture

We will follow the DFM principles to manufacture a product that meets your performance and quality standards.

4 Prototype

A preliminary model of your component & leveraging our in-house tool design.

5 Build & Develop

In this phase, any changes or updates to your prototype will be integrated into the final tooling and production.

6 Commercialization

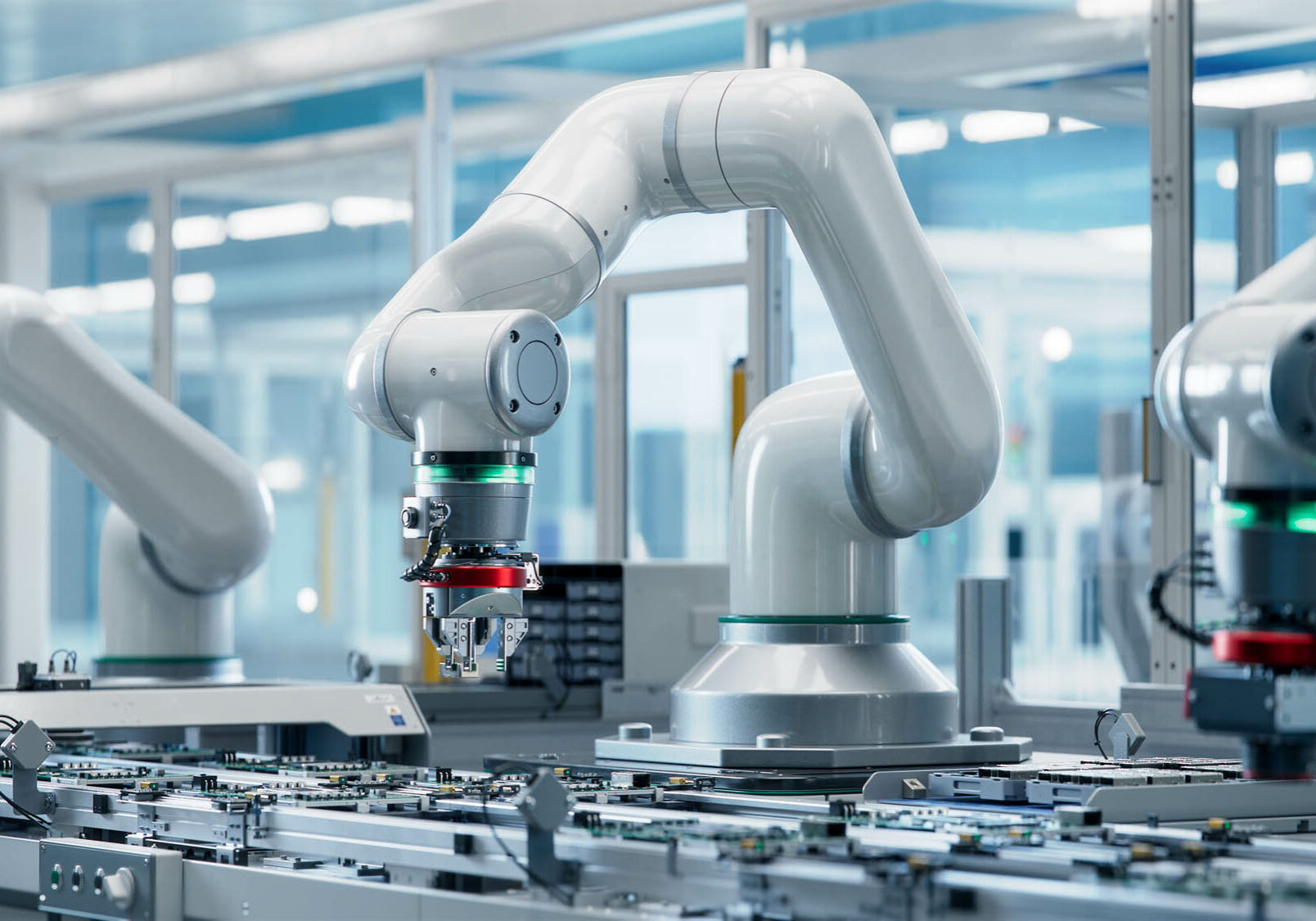

In our advanced manufacturing facility, we will produce the component to the quantity you require.

Our Facility

PDC boasts a 20,000-square-foot integrated tooling and manufacturing facility dedicated to healthcare and life sciences. Our facility is process-focused for ease of internal communication, efficient operations, and material flow. We are an exclusively cleanroom production and assembly facility featuring first-rate equipment for greater control over quality and lead times. We are proudly certified to the latest ISO 13485:2016 standard. As a professional and experienced molding company, we are a competent and trustworthy partner, whether you’re a startup company or blue-chip manufacturer.

As pioneers in breakthrough technologies, PDC proudly manufactures components & products for the medical device and life sciences industries that consistently meet exceedingly high requirements.