Our Capabilities

At PDC, we partner with our global customers to design, develop, and manufacture a variety of micro-molded components for various interventional procedures, ranging from large bore structural heart delivery systems to micro neurovascular components, through our market-leading micro injection molding solutions.

Our expertise in producing high-precision components ensures the reliability and performance of vascular and surgical devices, ultimately improving patient care and outcomes.

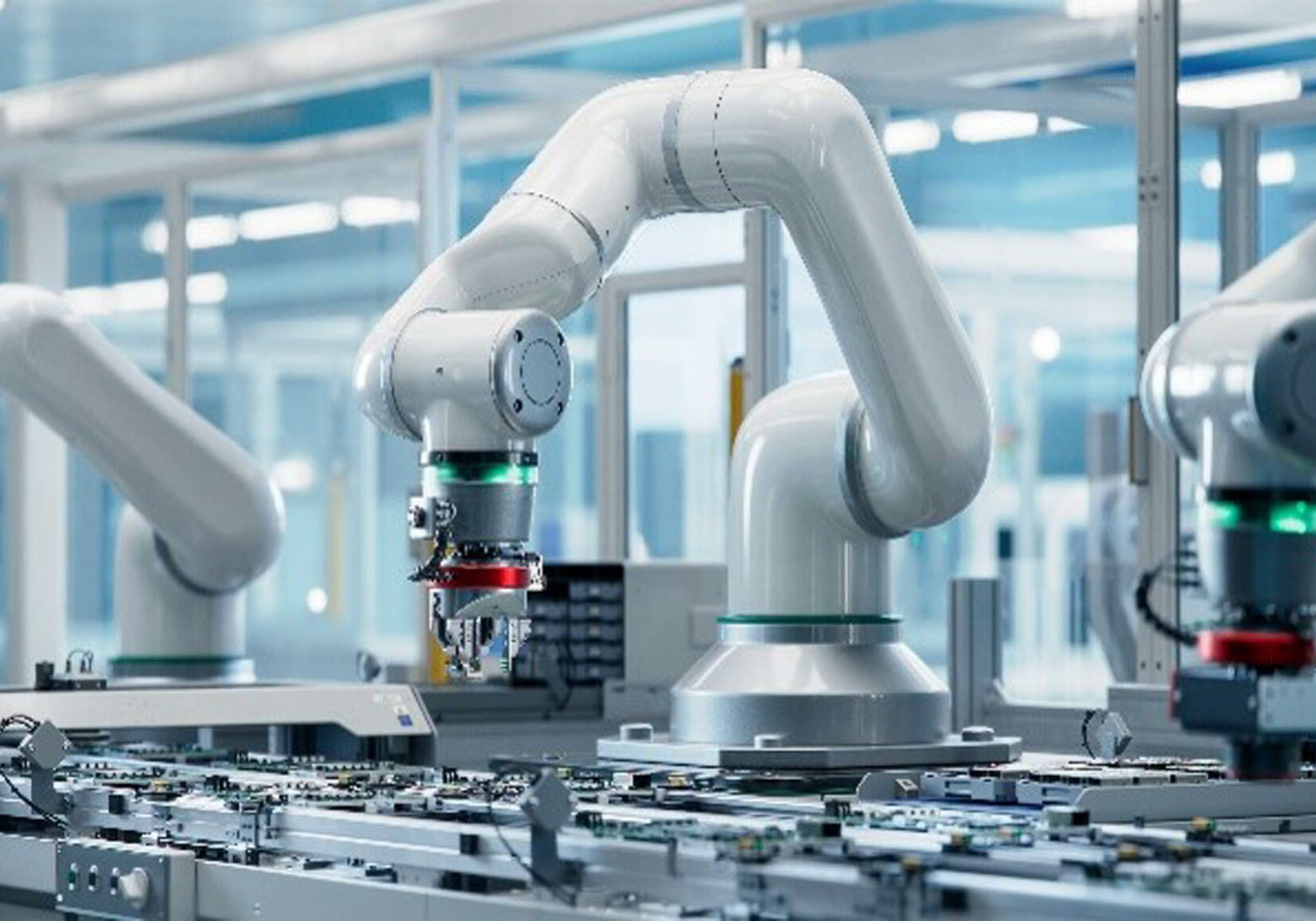

Our state-of-the-art micro injection molding technology allows us to manufacture intricate components with exceptional accuracy and tight tolerances. With a vertically integrated tool room equipped with advanced CNC Mills, EDM machines, and grinders, we maintain meticulous control over the entire production process.

This integration ensures rapid turnaround times, unparalleled precision, and consistent quality in every component we produce.

Why Choose Us?

Our success as a micro injection contract manufacturer stems from our expertise in micro tooling, precision micro molding, and over-molding sub-assemblies. Specializing in high-heat engineered resins, we offer extensive customization with additives and colors. Our vertically integrated facility supports the entire process from ideation to in-house tooling and molding, reducing risk and speeding time to market. We efficiently service projects from 10 to 10 million parts. Partner with us to experience the value of an experienced micro molding contract manufacturer.

Streamline Production and Enhance the Functionality

In addition to our precision molding capabilities, we offer a range of value-added services that enhance the functionality and efficiency of your vascular surgical devices:

- Catheter Tip Overmolding

- Ultrasonic and laser welding

- Pressure sensitive adhesives

- Laser etching

- Multi-step and multi-mode assembly

By incorporating these value-added processes, we streamline production, reduce time to market, and provide the flexibility to scale operations while maintaining tight control over lead times and ensuring high-quality outcomes.

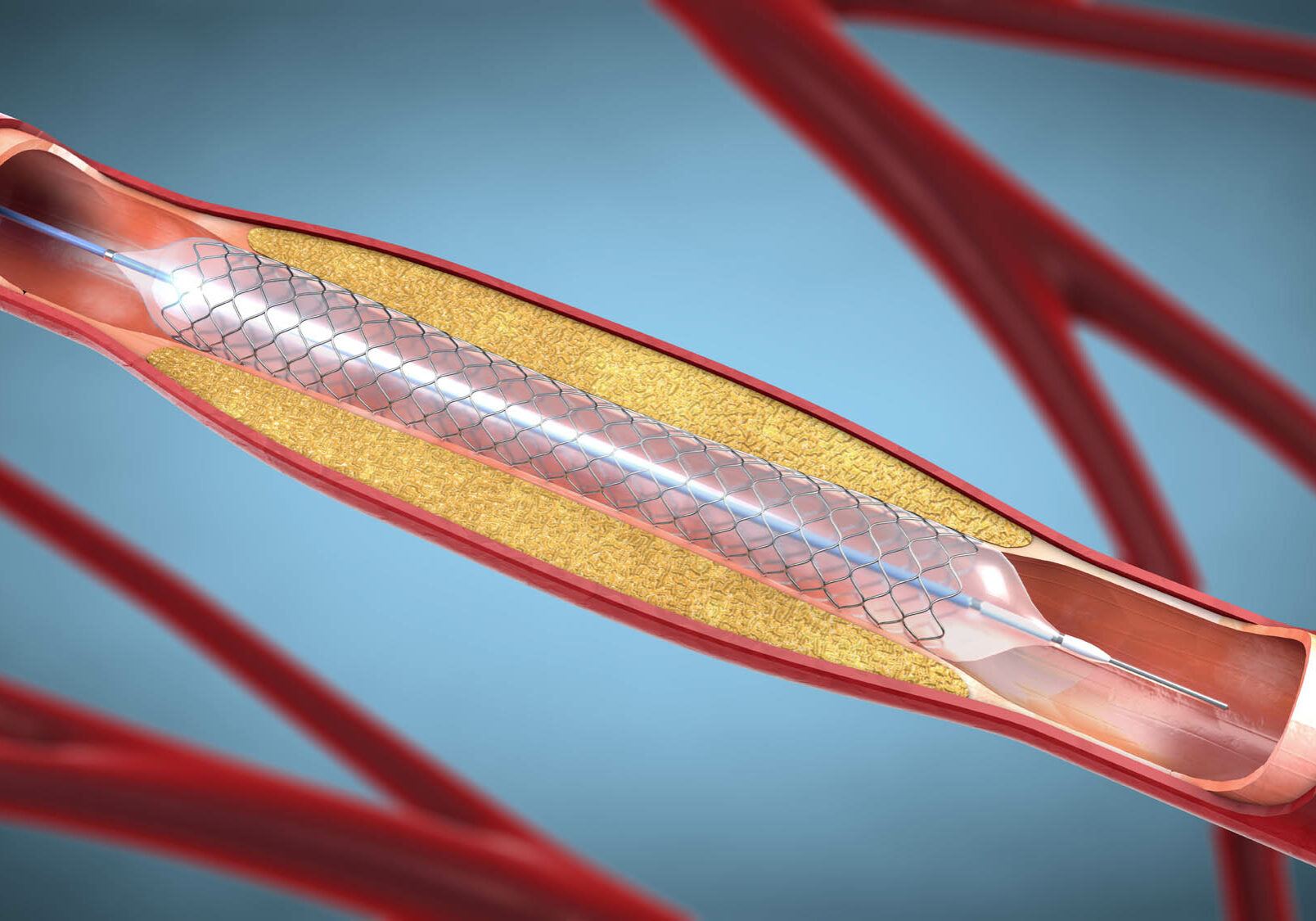

Key Components for Vascular Devices

As an experienced precision micro molding contract manufacturer, PDC understands the level of detail required for manufacturing critical components that make up vascular surgical devices. Below are examples of the types of components we specialize in:

- Anchoring and Fixation Devices

- Balloon Catheters

- Connector Interfaces

- Drug Delivery Ports

- Embolic Protection Devices

- Guidewire Components

- Housing and Enclosures

- Interventional Catheter Tips and Hubs

- Radiopaque Markers

- Seals and Gaskets

- Sheath Introducers

- Stent Delivery Systems

- Valve Components

- Vascular Access Ports

Upload your specifications and product models in the form below to start collaborating with an experienced micro molding engineering team.