The Importance of Measurement and Inspection in Micro Molding

Precision and reliability are key in the highly specialized field of medical technology. At PDC, we understand the critical role that meticulous measurement and inspection play in ensuring the quality of micro-molded components.

Our advanced automation and end-of-arm tooling solutions drive efficiency and quality in manufacturing, virtually eliminating the potential for human error and significantly reducing process variation by precisely controlling cycle time. PDC is dedicated to meeting our customer's needs by delivering the highest quality components with unparalleled precision and reliability.

Advanced Automation for Superior Quality

By integrating state-of-the-art robotics and smart manufacturing technologies, PDC ensures precision, scalability, and cost-effectiveness in our operations.

This approach allows us to consistently deliver highly reliable and consistent product quality, supporting our customers' growth by minimizing human error and maximizing throughput.

Our automated systems are designed to handle the most intricate and delicate components, ensuring every piece meets the highest quality standards.

In-Line Inspection: Setting a New Standard

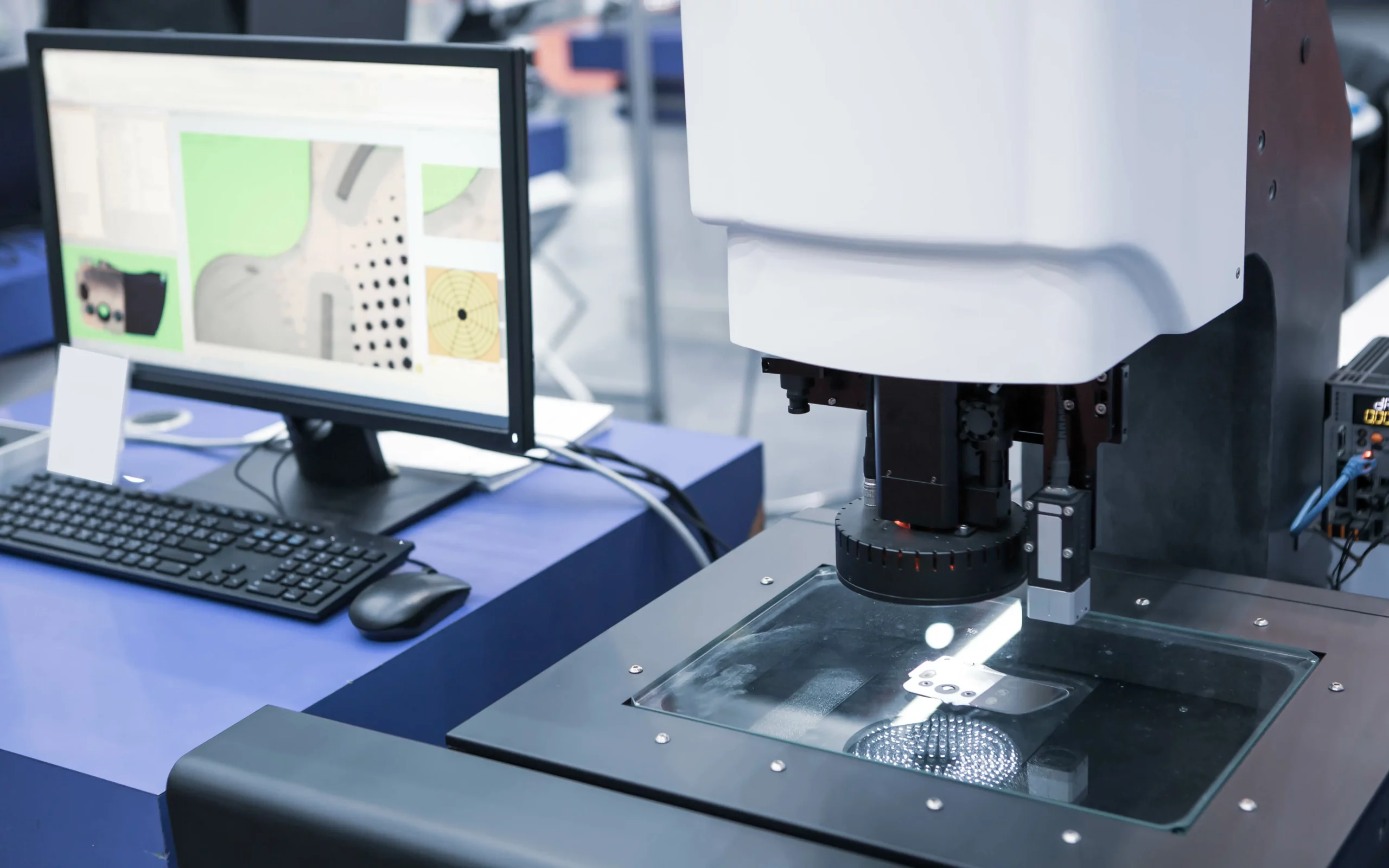

Our in-line inspection processes set a new standard for quality assurance. Utilizing advanced imaging and sensor technologies, we conduct real-time inspections during the manufacturing process.

Automated machine vision systems guarantee the highest levels of accuracy and compliance with stringent medical standards, significantly reducing lead times by eliminating the need for extensive post-production checks.

This means faster turnaround times and a more efficient path from concept to completion.

Cutting-Edge Inspection Equipment

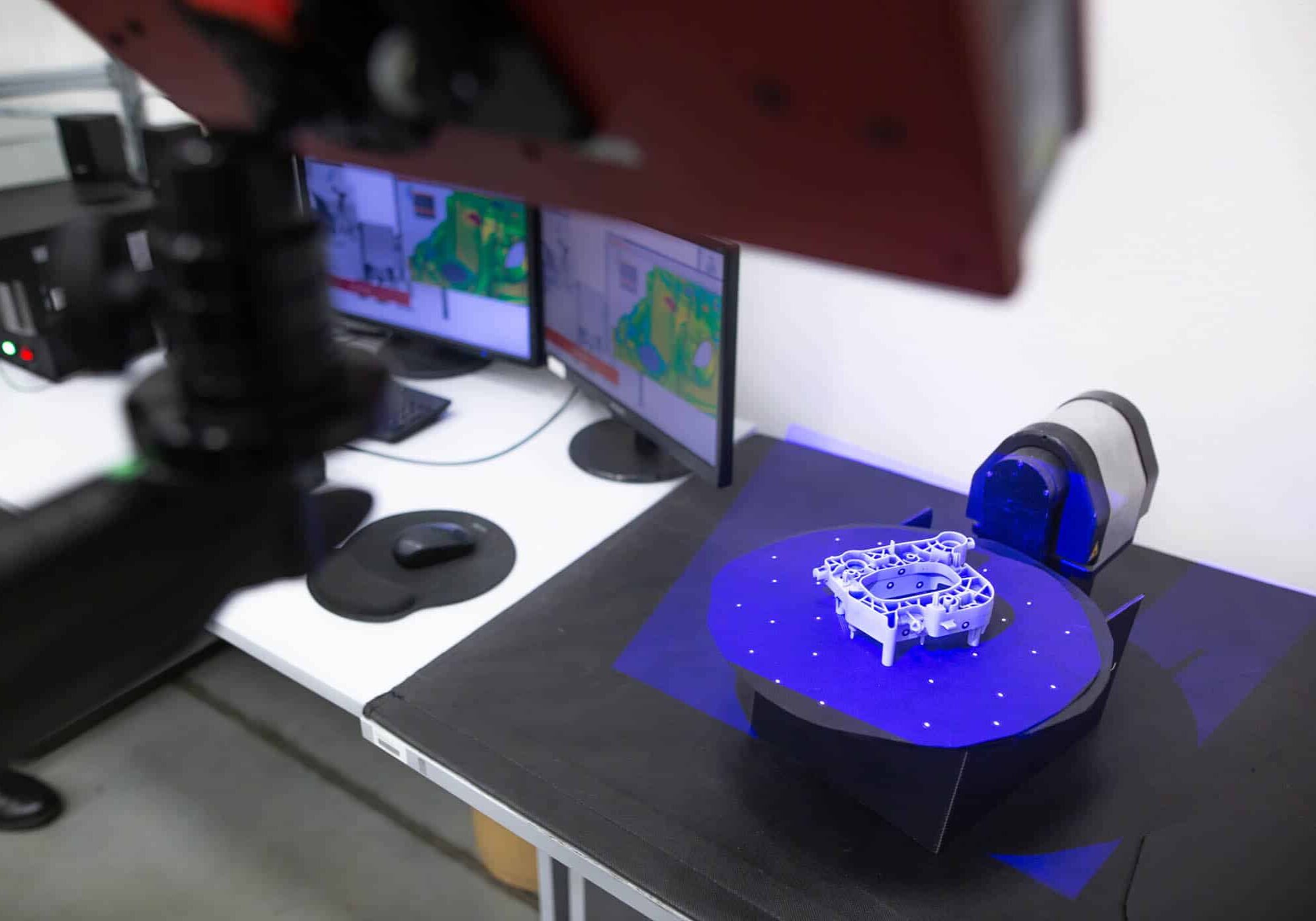

Our facilities are equipped with the latest in inspection technology, positioning us at the forefront of innovation in quality assurance.

From high-resolution imaging systems to sophisticated dimensional analysis tools, our inspection equipment ensures unparalleled accuracy in every measurement.

This technological advantage, combined with our expert team's meticulous attention to detail, ensures that even the most complex components meet the rigorous standards of the life sciences and medical device markets.

Measurement and Inspection Excellence at the Sub-Micron Level

At PDC, we ensure the highest precision and accuracy in measurement through advanced non-contact optical measurement systems.

- Confirm dimensions and process capability with non-contact optical systems.

- Measure surface flatness and achieve sub-micron precision using optical, laser, and white light interferometry techniques.

- Rapidly map and confirm complex surfaces using optical scanning technology.

We enhance measurement throughput and accuracy through advanced metrology techniques and systems.

- Perform GRR (Gage Repeatability and Reproducibility) and MSA (Measurement Systems Analysis) for automated measurement programs.

- Continuously advance metrology techniques, equipment, and software.

- Employ state-of-the-art measurement methods for customer products.

- Ensure every product exceeds industry standards, providing confidence and reliability.

Validation

Our validation process ensures that every product meets the exact specifications and stringent requirements of the life sciences and medical device industries. At PDC, we achieve a process performance index (CpK) of at least 1.33 for all critical dimensions measured in our validation process.

Utilizing advanced statistical techniques and comprehensive testing methodologies, we guarantee product reliability and performance from the initial prototype through mass production, achieving a best-in-class standard for quality assurance in contract manufacturing.

Our first article inspection process is designed to establish a benchmark of quality and precision for initial parts.

Next, we perform process capability studies to establish, with statistical significance, that validated processes will continue to meet predetermined acceptance criteria. This approach allows us to proactively confirm that our processes will meet the required product tolerances and specifications through the warrantied life of the production tool.

For critical process parameters, PDC continues to monitor process capability through the product lifecycle, enabling our quality team to control the production process.

In-Process Inspection

Through meticulous in-process inspection, we maintain unparalleled product quality and consistency. Our approach integrates real-time monitoring with validated inspection technologies, enabling immediate defect detection and ensuring each component adheres to the highest standards of precision and accuracy.

Our use of cutting-edge technology and measurement equipment enables our metrology engineers to rapidly measure and confirm that production parts meet all critical specifications and dimensions.

Our destructive AQL (Acceptable Quality Limit) sampling strategy allows us to assess product quality and durability at statistically significant thresholds. This ensures that only components meeting the highest standards proceed through our manufacturing line.

Our 100% visual inspection process is conducted by our trained staff to identify any imperfections, guaranteeing that every product meets all predetermined attribute specifications.

Get in Touch

If your company is ready to take advantage of the quality and expertise PDC provides, we want to hear from you! Please fill out the convenient contact form and we will be in touch shortly.

Micro Molding Solutions For Your Industry

Within the medical sector, micro molding has applications across both the medical device and life sciences markets. Learn more about the industries PDC proudly serves.

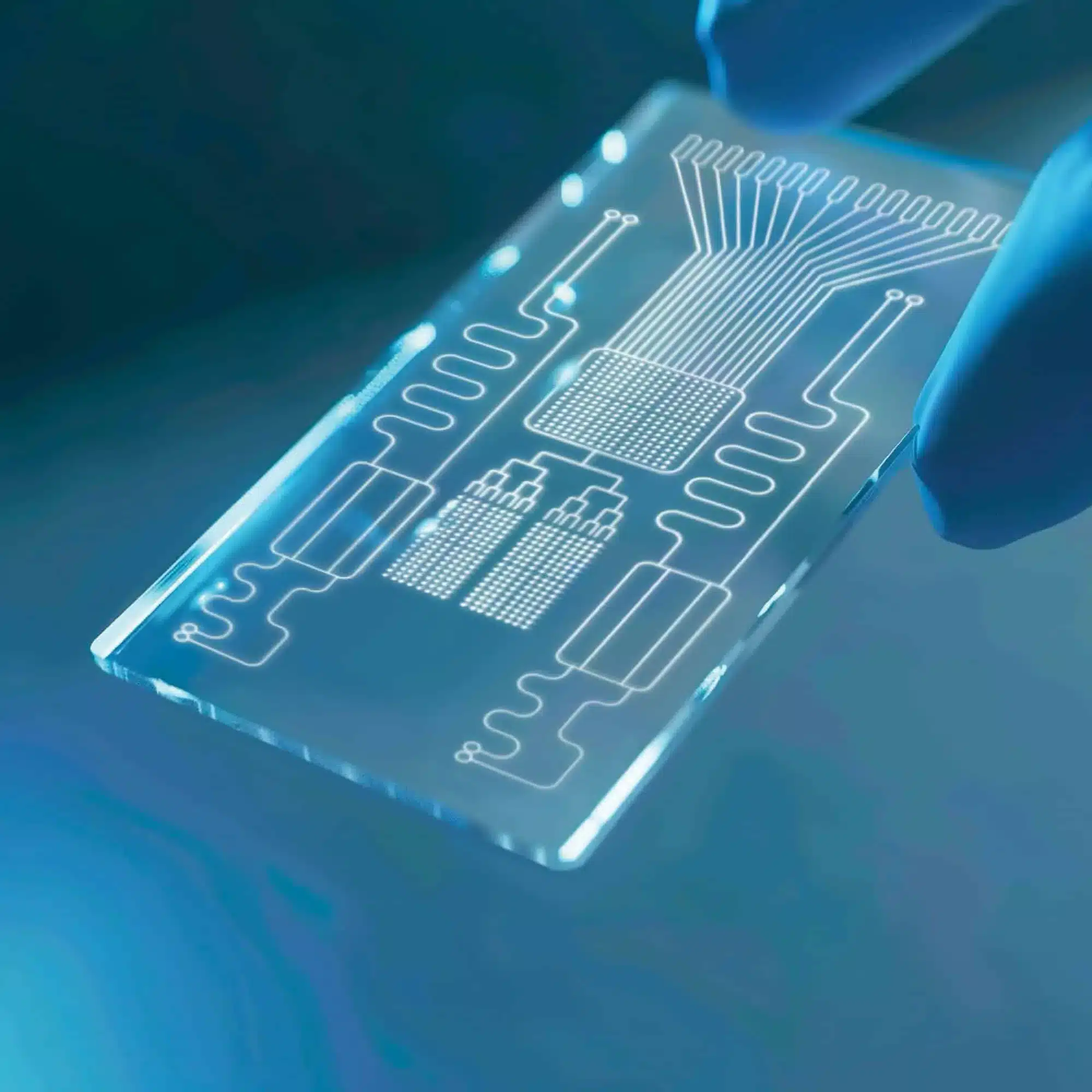

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. Explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. Explore the applications/products for advanced biopsy and key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. In this post, we’ll explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. In this post, we’ll explore three to five applications/products for advanced biopsy and delve into the key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

With our expansive manufacturing experience across various materials, we can identify the molding material based on your application to increase confidence that the material selected will meet your expectations in a production environment.