Your Precision Injection Molding Partner.

Our state-of-the-art clean rooms with cutting-edge injection molding machines are specifically designed to meet the exacting standards of our customers. Equipped with advanced air handling and filtration systems, our clean rooms ensure a low-contaminant environment for the precision molding of your products.

This dedication to maintaining the highest levels of cleanliness and hygiene is a cornerstone of our manufacturing process, reducing the risk of product contamination and ensuring the utmost quality and reliability.

Insert Molding and Over-Molding

Over-molding elevates the functionality and aesthetic appeal of medical devices by adding a soft plastic layer over a pre-existing plastic or metal part. This process not only enhances the product's durability and resistance to shock and vibration but also allows for the creation of ergonomic, patient-friendly medical devices with improved grip and comfort.

By utilizing our state-of-the-art over-molding techniques, we deliver products that stand out for their quality, performance, and patient-centric design.

We offer a diverse range of over-molding capabilities to meet various application needs. Our expertise includes:

- Plastic to Plastic

- Plastic to Tubing

- Plastic to Rod

- Plastic to Metal

These capabilities enable us to deliver high-quality, precision engineering components tailored to your specific device requirements.

- Capillary Components

- Connector Interfaces

- Diagnostic Cartridges

- Dispensing Nozzles

- Housing and Enclosures

- Lateral Flow Assay Components

- Lateral Flow Cell Assay Components

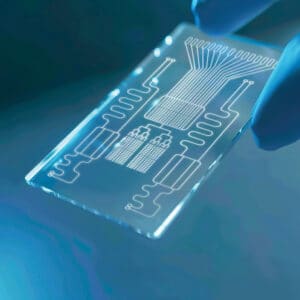

- Microfluidic Chips for qPCR

- Nano Dispensing Tips

- Needle Holders and Hubs

- Optical Components

- Reagent Reservoirs

- Sample Collection and Processing units

- Seals and Gaskets

- Sensor Housings with Low Autofluorescence

- Tamper Evident Caps

- Valve Components

- Cannula Assemblies

- Connector Interfaces

- Containers and Syringes

- Dispensing Nozzles

- Dosage Control Mechanisms

- Drive Unit Assemblies

- Fluid Path Assemblies

- Housing and Enclosures

- Luer Locks

- Needle-Free Injectors

- Needle Hubs and Covers

- Plunger Tips

- Reservoir Components

- Safety Mechanisms

- Seals and Gaskets

- Spring Retainers

- Tamper Evident Caps

- Valve Components

- Arthroscopic Instrument Components

- Bioresorbable Anchors

- Bone Graft Delivery Devices

- Compression Staples

- Connector Interfaces

- Graft Fixation Systems (GFS)

- Housing and Enclosures

- Implantable Fixation Devices

- Interference Screws

- Joint Repair Devices

- Seals and Gaskets

- Surgical Screws

- Suture Anchors

- Tendon Repair Anchors

- Valve Components

- Capillary Components

- Connector Interfaces

- Diagnostic Cartridges

- Dispensing Nozzles

- Housing and Enclosures

- Lateral Flow Assay Components

- Lateral Flow Cell Assay Components

- Microfluidic Chips for qPCR

- Nano Dispensing Tips

- Needle Holders and Hubs

- Optical Components

- Reagent Reservoirs

- Sample Collection and Processing Units

- Seals and Gaskets

- Sensor Housings with Low Autofluorescence

- Tamper Evident Caps

- Valve Components

- Anchoring and Fixation Devices

- Arthroscopy Camera Lenses

- Balloon Catheters

- Catheter Tips and Hubs

- Connector Interfaces

- Drainage Systems

- Drug Delivery Ports

- Drug Infusion Delivery Ports

- Fluid Management Systems

- Guidewire Components

- Housing and Enclosures

- Implantable Support Meshes

- Incontinence Devices

- Pelvic Floor Repair Devices

- Radiopaque Markers

- Seals and Gaskets

- Urethral Stents

- Valve Components

- Anchoring and Fixation Devices

- Balloon Catheters

- Connector Interfaces

- Drug Delivery Ports

- Embolic Protection Devices

- Guidewire Components

- Housing and Enclosures

- Interventional Catheter Tips and Hubs

- Microfluidic Devices

- Radiopaque Markers

- Seals and Gaskets

- Sheath Introducers

- Stent Delivery Systems

- Valve Components

- Vascular Access Ports

PDC is recognized for creating high feature resolution during the prototype phase in a time-friendly and budget-conscious manner. This allows our clients to test a component that matches their model in the desired resin. Our team works closely with our customers to refine and scale their designs, employing rapid prototyping and iterative development cycles to accelerate timelines and achieve high-quality outcomes for even the most complex medical devices.

Upload your specifications and product models in the form below to start collaborating with an experienced micro molding engineering team.

Micro Molding Solutions For Your Industry

Within the medical sector, micro molding has applications across both the medical device and life sciences markets. Learn more about the industries PDC proudly serves.

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. Explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. Explore the applications/products for advanced biopsy and key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. In this post, we’ll explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. In this post, we’ll explore three to five applications/products for advanced biopsy and delve into the key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.