Custom Designed and Manufactured Tooling at Plastic Design Company.

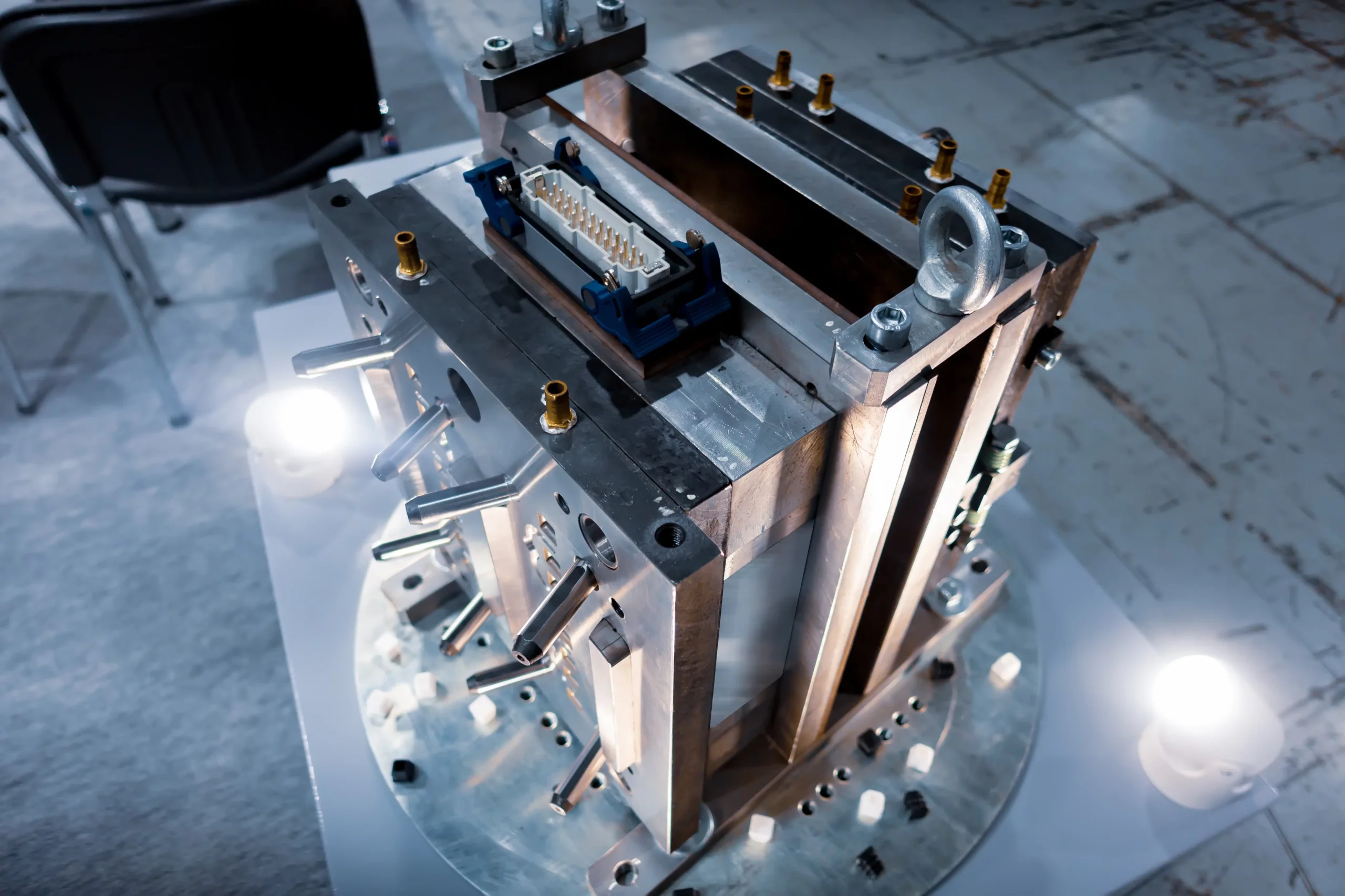

Plastic Design Company’s commitment to delivering a superior experience starts with strong technical collaboration while reviewing your micro-molded product specifications. With decades of experience in part and tool design, our engineering and manufacturing teams work closely with you from initial concept to high-volume production.

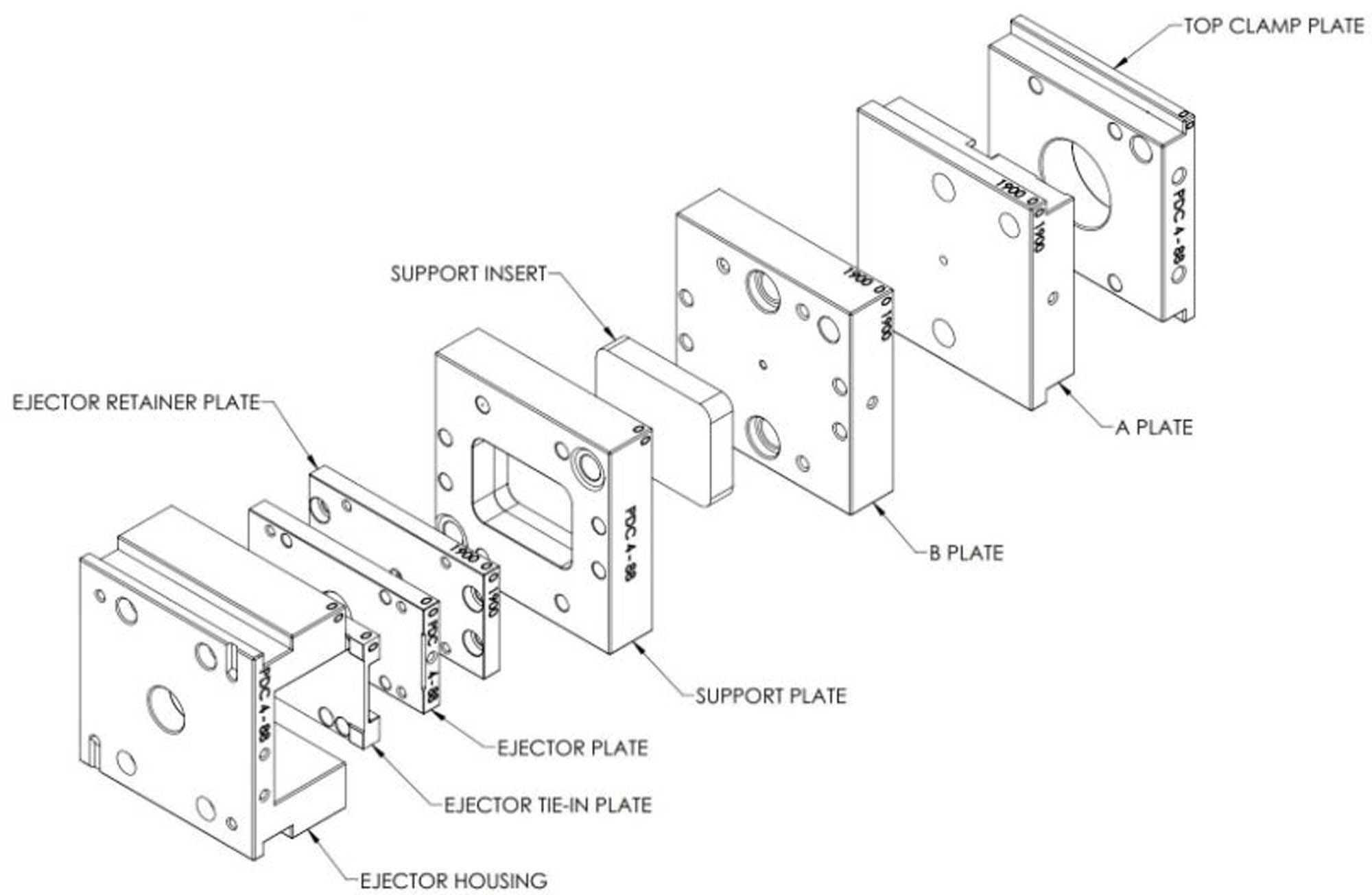

By focusing on design-for-manufacturing principles and selecting the proper tooling materials, we ensure the successful production of your precision molded components. Our technical team understands that designing micro injection molding tools requires balancing complexity, precision, and manufacturability.

Simplifying tool geometries and minimizing unnecessary features can streamline the process and reduce costs, while precision molding demands meticulous attention to detail in design, material selection, and process parameters to achieve the desired accuracy and quality.

Additionally, Plastic Design Company’s manufacturability considerations, such as tool accessibility, ease of maintenance, and scalability, are crucial for ensuring the long-term viability and sustainability of micro injection molding operations. Plastic Design Company's experienced tooling and mold design teams use in-house advanced technology to create precision molds for specific part needs. During mold construction, our tooling team is engaged with our automation engineers for part handling and design of end-of-arm tooling to handle micro components and how they may be presented to in-process equipment such as fixtures or inspection cameras.

Get in Touch

If your company is ready to take advantage of the quality and expertise Plastic Design Company provides, we want to hear from you! Please fill out the convenient contact form and we will be in touch shortly.

Micro Molding Solutions For Your Industry

Within the medical sector, micro molding has applications across both the medical device and life sciences markets. Learn more about the industries Plastic Design Company proudly serves.

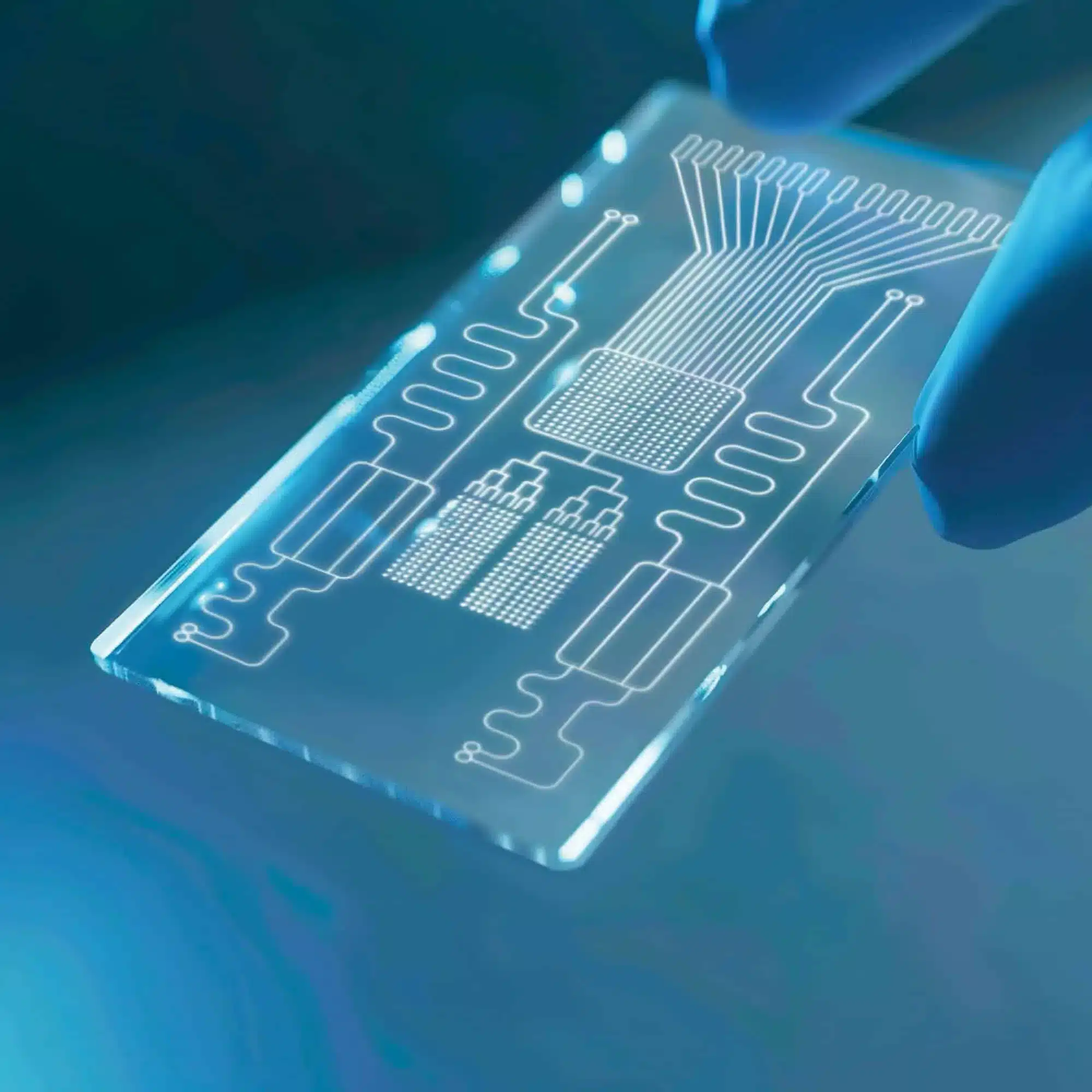

Plastic Design Company's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. Explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At Plastic Design Company, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

Plastic Design Company specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. Explore the applications/products for advanced biopsy and key considerations for injection molding to support these critical medical devices.

At Plastic Design Company, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

Plastic Design Company's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. In this post, we’ll explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At Plastic Design Company, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

Plastic Design Company specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. In this post, we’ll explore three to five applications/products for advanced biopsy and delve into the key considerations for injection molding to support these critical medical devices.

At Plastic Design Company, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

With our expansive manufacturing experience across various materials, we can identify the molding material based on your application to increase confidence that the material selected will meet your expectations in a production environment.