Enhancing Micro Molding with Value-Added Processes

To complement our precision micro molding capabilities, we offer various value-added processes that enhance the assembly and packaging of your components, ensuring they meet the highest standards of quality and functionality.

By limiting the overall number of suppliers in our customers' supply chain, this value-add approach streamlines production, reduces time to market, and provides the flexibility to scale operations while controlling lead times.

Versatile Marking Methods to Meet Your Needs: Pad Printing, Laser Marking, and Etching for Precision Molded Components and Assemblies

Pad Printing

Pad printing is an incredibly versatile marking solution that allows our precision injection molding services to offer detailed, high-quality printing on virtually any shape or surface. Ideal for complex medical devices, this technique ensures long-lasting, durable marks perfect for high-use items.

With our advanced color-matching capabilities, we can achieve precise branding and informational markings that meet our customer’s stringent requirements, ensuring clarity and compliance.

Laser Marking & Etching

Laser marking is essential for customers due to its precision, permanence, and speed. Our advanced laser marking technology delivers high-resolution, wear-resistant markings, ensuring traceability and compliance with medical regulations.

This non-contact method maintains the integrity of delicate components and provides an eco-friendly alternative to traditional methods. Laser etching allows for tracking specific product or manufacturing details directly on the part. Easily configurable, laser marking enables unique identifiers to be marked without complex reprogramming or retooling.

Labeling and Packaging

Our state-of-the-art labeling process ensures every product meets the stringent standards of our customers. PDC offers customizable labeling solutions that comply with global regulatory requirements.

Understanding the critical role of durability in medical environments, our labels are designed to withstand the rigors of storage, handling, and usage, ensuring that crucial information remains legible throughout the product's lifecycle.

Our advanced printing technology achieves unparalleled precision in every detail, from the smallest fonts to the most intricate graphics, enhancing both the functionality and the aesthetic appeal of your products.

Our packaging solutions prioritize the protection and sterility of your products. We employ cutting-edge techniques to ensure that components and products are securely housed from production through to end-user delivery.

We offer various packaging options, including tamper-evident features tailored to meet the specific needs of our customers and their markets.

Post-Mold Annealing

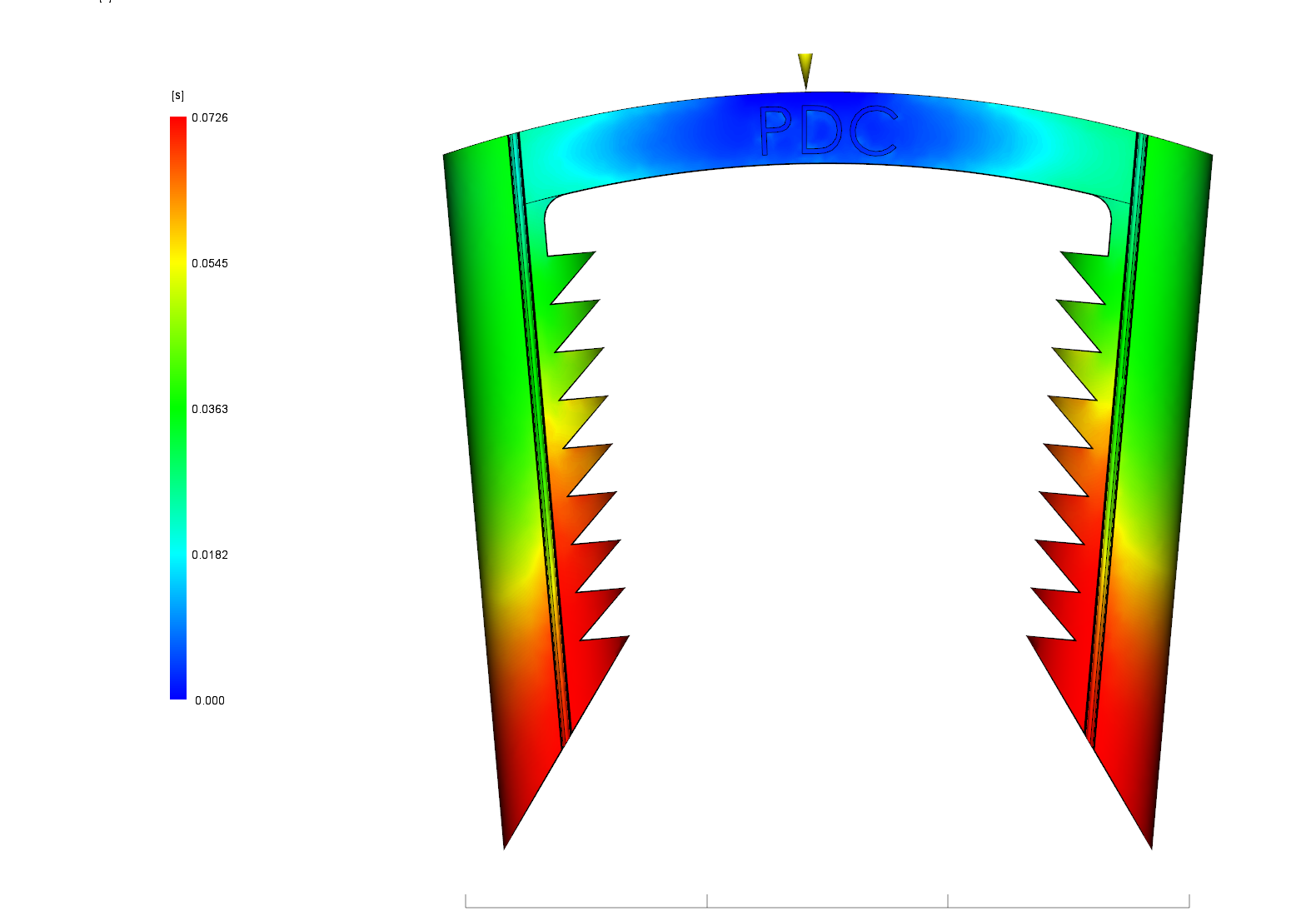

Annealing plastic parts after molding is a value-add process that removes molded-in stresses that are a natural part of injection molding. The annealing process involves heating parts to a specified temperature and duration and cooling them back to ambient temperature.

By utilizing specially designed fixturing and an oven with process control, critical dimensions can be maintained or even adjusted during the annealing process. Annealing is a popular choice where post-mold shrinkage characteristics are not fully characterized or known until initial sampling.

Precision Surface Finish Treatments

Corona Treatment

Corona treatment is an invaluable process in precision injection molding. A high-voltage, high-frequency electrical discharge alters and reduces the surface energy of the polymer substrate. By applying a high-voltage, high-frequency electrical discharge, it effectively alters the surface energy of polymer-based substrates.

This enhancement in surface wettability ensures superior bonding and coating quality, enabling the production of products with increased reliability and durability.

Plasma Treatment

Plasma treatment stands at the forefront of surface modification technologies, offering unmatched precision and versatility. This environmentally friendly process cleans, activates, and etches surfaces at the molecular level without compromising the bulk properties of the material.

Plasma treatment means achieving optimal surface conditions for bonding, printing, and coating applications, significantly improving product performance and longevity.

Commitment to Excellence

At PDC, we are dedicated to providing value-added processes for our customers. Our comprehensive approach ensures that products meet customer specifications and industry standards. Our commitment to exceptional confidence and reliability supports our customers’ success in their respective markets.

Get in Touch

If your company is ready to take advantage of the quality and expertise PDC provides, we want to hear from you! Please fill out the convenient contact form and we will be in touch shortly.

Micro Molding Solutions For Your Industry

Within the medical sector, micro molding has applications across both the medical device and life sciences markets. Learn more about the industries PDC proudly serves.

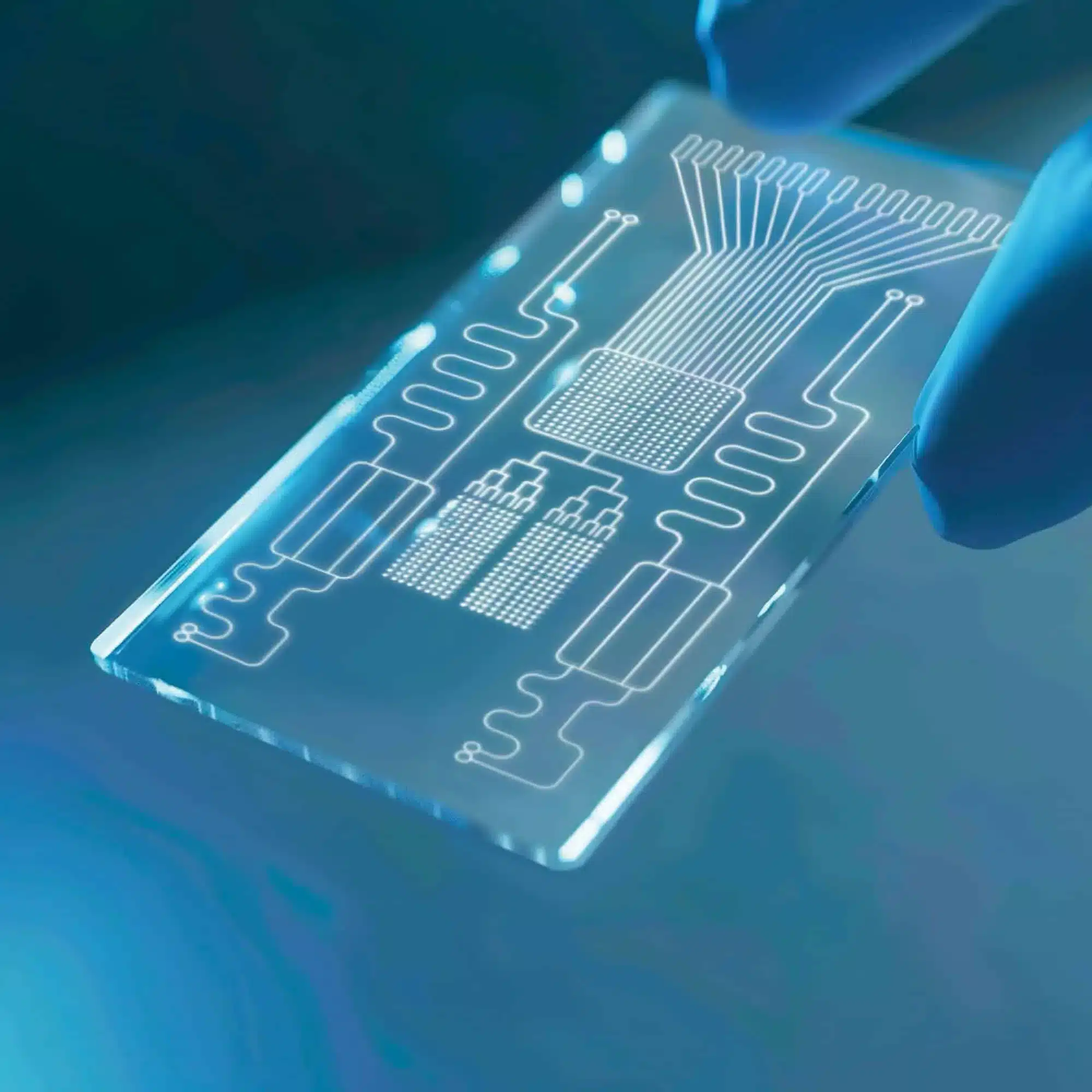

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. Explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. Explore the applications/products for advanced biopsy and key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

PDC's experience with COP/COC thermoplastics while micro molding, combined with core insert molding competency, supports flowcell technology used in next-generation sequencing, which was previously only served by glass lithography.

In drug delivery, precision is paramount to ensuring patients receive the proper medication in the correct dosage at the right time. Micro injection molded components have emerged as essential tools in achieving this level of accuracy and control. In this post, we’ll explore various applications in drug delivery where these tiny yet powerful components are making a substantial impact.

We’re committed to leveraging our expertise in precision injection molding and PEEK material to drive innovation in orthopedic sports medicine. By partnering with leading medical device companies and orthopedic surgeons, we strive to deliver advanced solutions that improve patient outcomes and quality of life.

As a leading precision injection molding company dedicated to driving innovation in the proteomics and genomics sector, we are pleased to share our expertise and commitment to supporting advancements in Digital PCR (dPCR) and Droplet Digital PCR (ddPCR). At PDC, we recognize the critical role that precision engineering plays in pushing the boundaries of scientific discovery, and we are excited to be at the forefront of this transformative journey.

PDC specializes in precision injection molding solutions that cater to the unique needs of the urology and women’s health market segments. Our commitment to innovation and quality drives us to support advanced biopsy applications with unparalleled precision and reliability. In this post, we’ll explore three to five applications/products for advanced biopsy and delve into the key considerations for injection molding to support these critical medical devices.

At PDC, we’re committed to driving advancements in precision injection molding to meet the evolving needs of the vascular surgery market. We're empowering medical professionals with cutting-edge devices that improve patient care and outcomes by harnessing the power of radiopaque inserts and polymers and adhering to stringent quality standards.

Contact us today to learn how our value-added processes can support your next project and drive your success.